fischer Construction Monitoring

The innovation for added security

fischer Construction Monitoring’s mission is to make the world a little bit safer. We offer an unprecedented combination of a smart monitoring tool and strong fastenings with our system solutions to document and monitor facilities and buildings. Join us in taking a key step towards a digital future in construction.

Even if everything has been correctly planned and calculated, the status of fastenings in or on buildings is often still a black box between on-site maintenance intervals. This is where fischer Construction Monitoring provides an effective solution.

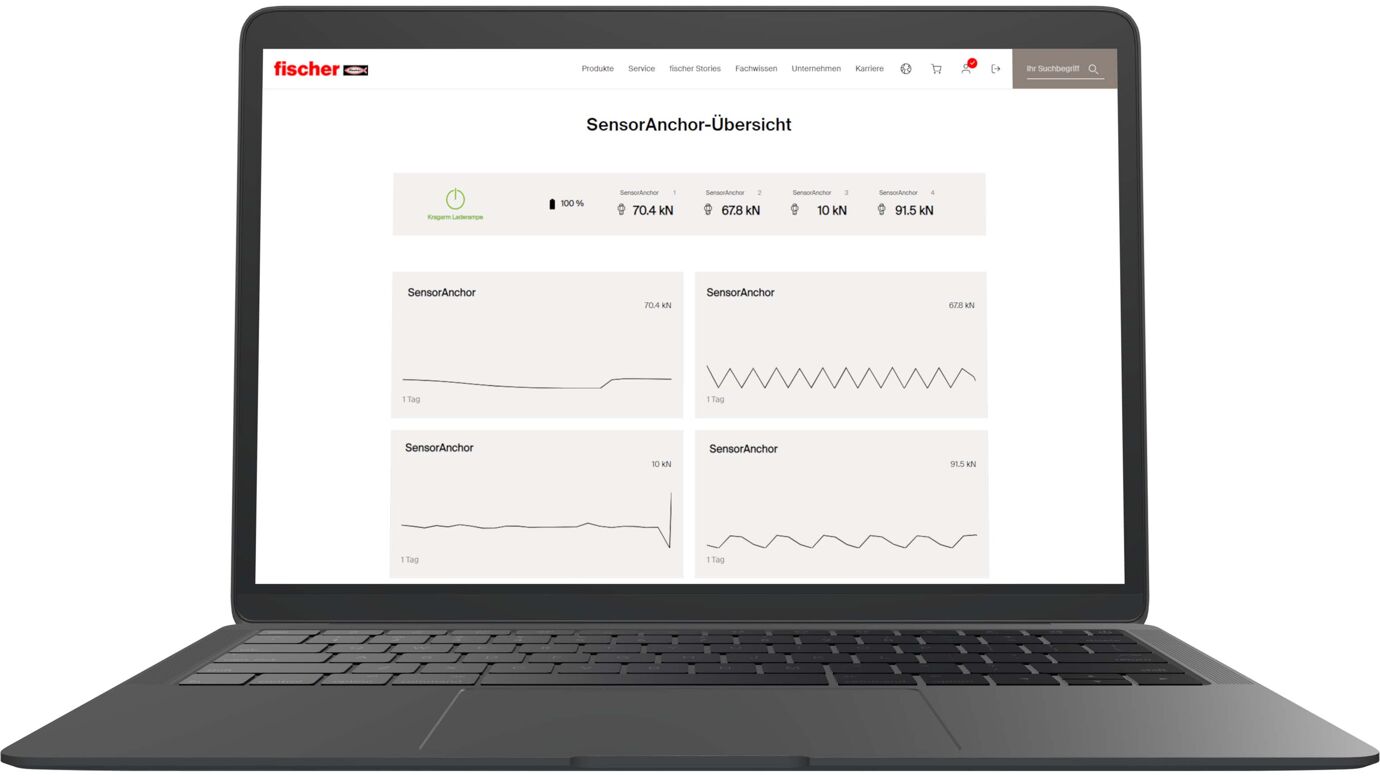

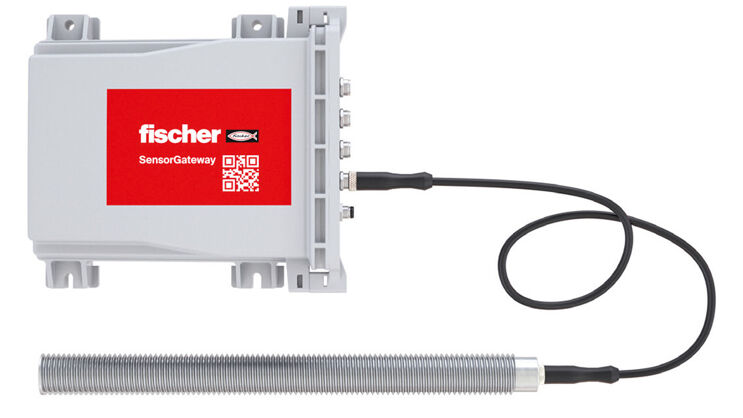

Creeping, shrinking and setting construction materials - changes and deformations such as these present structural engineers with challenges when it comes to tunnels, wind turbines and bridges. It’s a good thing that our SensorAnchor provides a reliable, all-in-one solution offering maximum data transparency through the real-time transfer of preload and operating forces. This provides an early automatic warning for critical connections, allowing you to easily and conveniently monitor the data on the end device of your choice, resulting in minimal maintenance for structures of all sizes.

A built-in sensor in the anchor transfers real-time preload and operational forces to the fischer Construction Monitoring evaluation platform. This data can be accessed at any time and is used for the early detection of vulnerable connections.

Every structure is different. That’s why being able to rely on individual safety assessment parameters is all the more important. fischer Construction Monitoring and an integrated warning system allow you to set critical limits in the system. Once these limits have been reached, you’ll automatically receive a push notification.

Every screw has to sit right. Users are on the safe side with our SensorDisc, a digital fastening to check and document conventional screw connections. It all works exactly the same as conventional washers, be it during initial installation or retrofits. Simply scan your SensorDisc in the fischer PRO app to obtain a quick and convenient reading of the recorded data.

Any place, any time. Identify all types of screw connection failures early on and increase their safety and service life with fischer’s new SensorDisc.

Simple, quick and precise. Here’s how to read the fischer SensorDisc via NFC transfer. Simply select the disc in the fischer PRO app and measure the current force level. All values are automatically stored in the cloud.

Do you have any questions or are you interested in using our products? Then fill in the following brief contact form. Our fischer Experts will be in touch with you shortly.